226x Filetype PDF File size 0.29 MB Source: www.iise.org

What You Need to Know About Mistake-Proofing (Poka Yoke)

The goal of mistake-proofing or Poka Yoke is simple: to eliminate mistakes.

In order to eliminate mistakes, we need to modify processes so that it is impossible to make them in the

first place. With mistake-proofing solutions, many repetitive tasks that depend upon the memory of the

worker are built into the process itself. Mistake-proofing frees the time and minds of the workforce to

pursue more creative and value-adding activities.

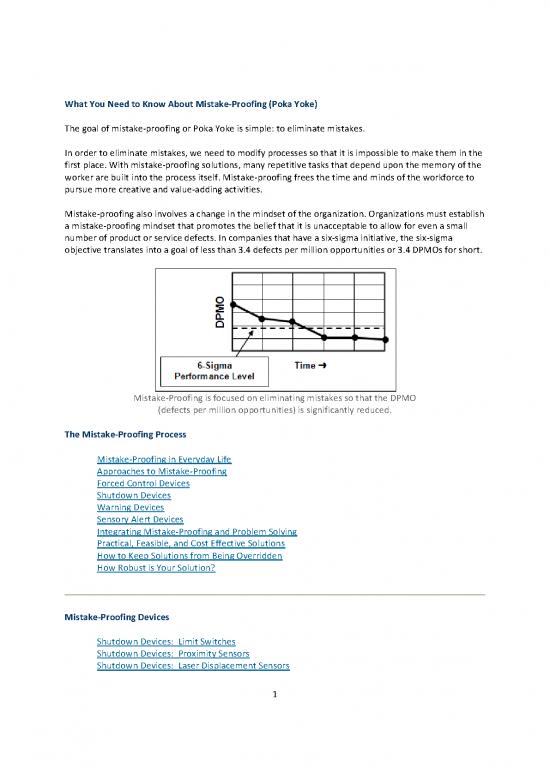

Mistake-proofing also involves a change in the mindset of the organization. Organizations must establish

a mistake-proofing mindset that promotes the belief that it is unacceptable to allow for even a small

number of product or service defects. In companies that have a six-sigma initiative, the six-sigma

objective translates into a goal of less than 3.4 defects per million opportunities or 3.4 DPMOs for short.

Mistake-Proofing is focused on eliminating mistakes so that the DPMO

(defects per million opportunities) is significantly reduced.

The Mistake-Proofing Process

Mistake-Proofing in Everyday Life

Approaches to Mistake-Proofing

Forced Control Devices

Shutdown Devices

Warning Devices

Sensory Alert Devices

Integrating Mistake-Proofing and Problem Solving

Practical, Feasible, and Cost Effective Solutions

How to Keep Solutions from Being Overridden

How Robust is Your Solution?

Mistake-Proofing Devices

Shutdown Devices: Limit Switches

Shutdown Devices: Proximity Sensors

Shutdown Devices: Laser Displacement Sensors

1

Shutdown Devices: Visions Systems

Shutdown Devices: Counters and Timers

Shutdown Devices: Photoelectric Sensors

Shutdown Devices: Ultrasonic Sensors

Shutdown Devices: Families of Process Measurement Instrumentation

Shutdown Devices: Families of Specialty Sensors

Go to top

Examples of Mistake-Proofing

The best way to teach Mistake-Proofing is through examples. Mistake-Proof It! Web- and Computer-

Based Training has over 150 examples of Mistake-Proofing in a variety of settings including High Volume

Manufacturing, Assembly Operations, Job Shops, Process Industries, Equipment Set-Up Reduction, and

the office. For more information on the training and to try a free demo lesson, click here. Courses start

at just $59 each.

Important Root Cause Analysis Tools for Mistake-Proofing

The 5-Whys

Ask “why?” 5 (or more) times to tunnel down into the root cause. The answer to the first why is almost

always an obvious symptom. The secret behind the 5-whys technique is to accept the answer, but to

then ask why again and again until the root cause is uncovered. Sometimes, the root cause can be found

at the fourth or five why. Often, however, you must ask “why?” more than 5-times.

What is—What isn’t Analysis

Often, listing what a problem is and isn’t helps get to the root cause by a matter of elimination. What Is-

What’s Isn’t questions include: What happened? & What might you have expected to happen but

didn’t? Where did it happen? & Where didn’t it happen? What changed in the process? & What didn’t

change in the process? Which supplier was involved? & Which wasn’t?

Data Collection & Data Display

Fact-based problem-solving – that’s what root cause analysis is all about. To get facts, collect data from

the process or create data related to the process. To get facts, we collect data from the process or

create data related to the process. Once data have been collected, there are a number of simple

methods to analyze data using graphical display techniques. Data display tools turn the data into

pictures and a picture of what has happened often leads to the root cause.

Failure Analysis

Techniques for collecting data from failure analysis include reviewing physical evidence (much like crime

scene investigation), special testing, accelerated testing, and finite element analysis. You might need

2

special tools or techniques to review the physical evidence (e.g. microscopy to look at a break surface)

or you might need to conduct special testing on the product or process itself. Use well-designed and

easy to use data collection forms. Good detective skills can turn interviews into effective data collection

events. One of the most powerful, but also most under-used, data collection tools is a concentration

diagram.

Simulations

Simulations can be used to collect data using computer modeling software, pilot-plant experimentation,

and if need be, experimentation using the actual process itself. With the proper model, a computer

could help point the way to the root cause. Or it might be pilot-plant trials or experimentation using the

“real” process that generates the data that leads to the root cause. In any case, if you can recreate the

problem, you are more apt to find the root cause.

Statistical Analysis

While data display methods are usually easier to use, sometimes a statistical analysis technique is

needed to wring the real meaning out of the data. SPC control charts will actively signal a problem with

a process. Correlation and regression analysis and multivariate analysis may be needed to make sense of

the data.

The “Root Cause” Question

Once you think you are at the root cause, take a step back and ask yourself the root cause question–

“Does this cause explain all that is known about what the problem is, as well as all that is known about

what the problem isn’t?“ This is really a two-part question: make sure the root cause found fits both the

“is” and the “isn’t” sections of the question. If the cause being tested doesn’t fit both, then it’s probably

not the root cause.

3

no reviews yet

Please Login to review.