259x Filetype XLSX File size 0.04 MB Source: content.web-repository.com

Sheet 1: SORT

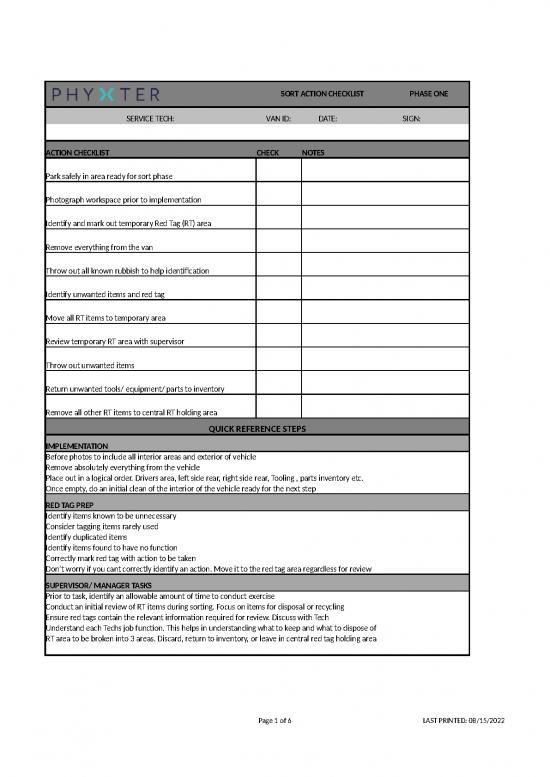

| SORT ACTION CHECKLIST | PHASE ONE | |||

| VAN ID: | DATE: | SIGN: | ||

| ACTION CHECKLIST | CHECK | NOTES | ||

| Park safely in area ready for sort phase | ||||

| Photograph workspace prior to implementation | ||||

| Identify and mark out temporary Red Tag (RT) area | ||||

| Remove everything from the van | ||||

| Throw out all known rubbish to help identification | ||||

| Identify unwanted items and red tag | ||||

| Move all RT items to temporary area | ||||

| Review temporary RT area with supervisor | ||||

| Throw out unwanted items | ||||

| Return unwanted tools/ equipment/ parts to inventory | ||||

| Remove all other RT items to central RT holding area | ||||

| QUICK REFERENCE STEPS | ||||

| IMPLEMENTATION | ||||

| Before photos to include all interior areas and exterior of vehicle | ||||

| Remove absolutely everything from the vehicle | ||||

| Place out in a logical order. Drivers area, left side rear, right side rear, Tooling , parts inventory etc. | ||||

| Once empty, do an initial clean of the interior of the vehicle ready for the next step | ||||

| RED TAG PREP | ||||

| Identify items known to be unnecessary | ||||

| Consider tagging items rarely used | ||||

| Identify duplicated items | ||||

| Identify items found to have no function | ||||

| Correctly mark red tag with action to be taken | ||||

| Don’t worry if you cant correctly identify an action. Move it to the red tag area regardless for review | ||||

| SUPERVISOR/ MANAGER TASKS | ||||

| Prior to task, identify an allowable amount of time to conduct exercise | ||||

| Conduct an initial review of RT items during sorting. Focus on items for disposal or recycling | ||||

| Ensure red tags contain the relevant information required for review. Discuss with Tech | ||||

| Understand each Techs job function. This helps in understanding what to keep and what to dispose of | ||||

| RT area to be broken into 3 areas. Discard, return to inventory, or leave in central red tag holding area | ||||

| STRAIGHTEN ACTION CHECKLIST | PHASE TWO | |||

| VAN ID: | DATE: | SIGN: | ||

| ACTION CHECKLIST | CHECK | NOTES | ||

| Plan layout for all areas of the van including hazard identification | Keep a written location plan so you can use it for future reference | |||

| Clean all storage equipment before installation | Use an apprentice if possible | |||

| Install all storage equipment | Roof racks, shelving, racks, shadow boards, partitions, etc. | |||

| Label or post signs for all locations | If regularly changing locations, use magnetic signs | |||

| Install all secondary storage equipment | Tool box foam, smaller shelves, storage bins, etc. | |||

| Install safety labeling to identify hazards | Ensure safety signage meets the appropriate standard | |||

| Line mark floor locations as needed | ||||

| QUICK REFERENCE STEPS | ||||

| DOCUMENT HAZARDS, TOOLS, AND INVENTORY | ||||

| Keep a log of all equipment, tools and inventory. Ensure you include the location. You will need this in the 4th Step | ||||

| Ensure you identify as a group all hazards associated with your operations | ||||

| Make sure you have the right supplies to start labelling | ||||

| For safety and inspection purposes, make sure you review the relevant guidelines or standards | ||||

| Don’t forget the drivers cabin! | ||||

| SHINE ACTION CHECKLIST | PHASE THREE | |||

| VAN ID: | DATE: | SIGN: | ||

| ACTION CHECKLIST | CHECK | NOTES | ||

| Take photos of all areas of the van for reference | ||||

| Inspect all tooling and equipment | Do this prior to placing back in its location | |||

| Remove and red tag items not meeting the inspection criteria for future evaluation | Don’t forget to replace the item if it cant be fixed | |||

| Conduct maintenance on equipment and tool if required | ||||

| Clean everything | ||||

| Put everything back in its designated location | Initially it may not fit or seem logical, adjust as required. | |||

| Photograph the final product | Good to compare the before and after photographs | |||

| Start developing cleaning and inspection checklist | Should be relevant to the van fit out | |||

| QUICK REFERENCE STEPS | ||||

| PREPARATION AND IMPLEMENTATION | ||||

| Conduct a deep clean of the vehicle inside and out | ||||

| Provide the right cleaning supplies to conduct the task | ||||

| Ensure all employees are trained on how to inspect all tooling and equipment | ||||

| Start developing an inspection and cleaning checklist for each vehicle based on its fit out | ||||

| Review all vans for conformity as required | ||||

| Supervisors - Ensure you congratulate your Techs on a great job so far! | ||||

no reviews yet

Please Login to review.