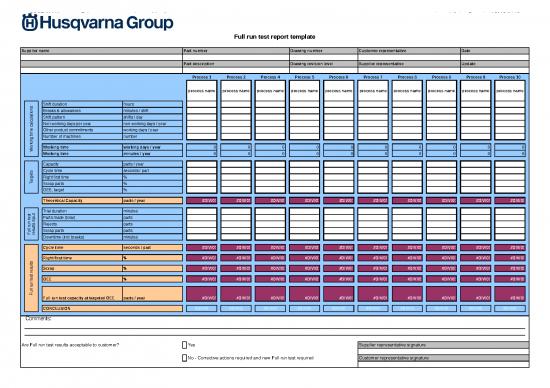

| Full run test report template

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Supplier name |

Part number |

Drawing number |

Customer representative |

Date |

|

|

|

|

|

|

Part description |

Drawing revision level |

Supplier representative |

Update |

|

|

|

|

|

|

|

|

|

|

|

Process 1 |

|

Process 2 |

|

Process 4 |

|

Process 5 |

|

Process 6 |

|

Process 7 |

|

Process 8 |

|

Process 8 |

|

Process 9 |

|

Process 10 |

|

|

|

|

|

|

|

process name |

|

process name |

|

process name |

|

process name |

|

process name |

|

process name |

|

process name |

|

process name |

|

process name |

|

process name |

|

|

Working time calculations |

|

Shift duration |

hours |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Breaks & allowances |

minutes / shift |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Shift pattern |

shifts / day |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Non working days per year |

non-working days / year |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Other product commitments |

working days / year |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Number of machines |

number |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Working time |

working days / year |

|

0 |

|

0 |

|

0 |

|

0 |

|

0 |

|

0 |

|

0 |

|

0 |

|

0 |

|

0 |

|

|

|

Working time |

minutes / year |

|

0 |

|

0 |

|

0 |

|

0 |

|

0 |

|

0 |

|

0 |

|

0 |

|

0 |

|

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Targets |

|

Capacity |

parts / year |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Cycle time |

seconds / part |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Right first time |

% |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Scrap parts |

% |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OEE, target |

% |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Theoretical Capacity |

parts / year |

|

#DIV/0! |

|

#DIV/0! |

|

#DIV/0! |

|

#DIV/0! |

|

#DIV/0! |

|

#DIV/0! |

|

#DIV/0! |

|

#DIV/0! |

|

#DIV/0! |

|

#DIV/0! |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Full run test results input |

|

Trial duration |

minutes |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Parts made (total) |

parts |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Rejects |

parts |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Scrap parts |

parts |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Downtime (incl breaks) |

minutes |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Full run test results |

|

Cycle time |

seconds / part |

|

#DIV/0! |

|

#DIV/0! |

|

#DIV/0! |

|

#DIV/0! |

|

#DIV/0! |

|

#DIV/0! |

|

#DIV/0! |

|

#DIV/0! |

|

#DIV/0! |

|

#DIV/0! |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Right first time |

% |

|

#DIV/0! |

|

#DIV/0! |

|

#DIV/0! |

|

#DIV/0! |

|

#DIV/0! |

|

#DIV/0! |

|

#DIV/0! |

|

#DIV/0! |

|

#DIV/0! |

|

#DIV/0! |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Scrap |

% |

|

#DIV/0! |

|

#DIV/0! |

|

#DIV/0! |

|

#DIV/0! |

|

#DIV/0! |

|

#DIV/0! |

|

#DIV/0! |

|

#DIV/0! |

|

#DIV/0! |

|

#DIV/0! |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OEE |

% |

|

#DIV/0! |

|

#DIV/0! |

|

#DIV/0! |

|

#DIV/0! |

|

#DIV/0! |

|

#DIV/0! |

|

#DIV/0! |

|

#DIV/0! |

|

#DIV/0! |

|

#DIV/0! |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Full run test capacity at targeted OEE |

parts / year |

|

#DIV/0! |

|

#DIV/0! |

|

#DIV/0! |

|

#DIV/0! |

|

#DIV/0! |

|

#DIV/0! |

|

#DIV/0! |

|

#DIV/0! |

|

#DIV/0! |

|

#DIV/0! |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CONCLUSION |

|

#DIV/0! |

|

#DIV/0! |

|

#DIV/0! |

|

#DIV/0! |

|

#DIV/0! |

|

#DIV/0! |

|

#DIV/0! |

|

#DIV/0! |

|

#DIV/0! |

|

#DIV/0! |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Comments: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Are Full run test results acceptable to customer? |

|

|

|

|

|

Yes |

|

|

|

|

|

|

|

|

|

Supplier representative signature |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

No - Corrective actions required and new Full run test required |

|

|

|

|

|

|

|

|

|

Customer representative signature |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Full run test report template, instructions

|

|

|

|

|

|

|

|

|

|

|

|

|

| White fields to be filled in |

|

|

|

|

|

|

|

|

Example 1 |

|

Example 2 |

|

|

Working time calculations |

|

Shift duration |

hours |

|

How long is each shift? (normally 8 or 12 hours) |

|

8 |

|

12 |

|

|

|

Breaks & allowances |

mins / shift |

|

How many minutes are allowed for breaks, start of shift, cleaning, handover, etc ? |

|

50 |

|

70 |

|

|

|

Shift pattern |

shifts / day |

|

How many shifts per day ( normally 1,2 or 3) are used? |

|

3 |

|

2 |

|

|

|

Non working days per year |

non-working days / year |

|

Number of planned non-working days, when the plant is closed. Includes weekends, summer / Christmas holidays, National holidays etc. |

|

116 |

|

12 |

|

|

|

Other product commitments |

working days / year |

|

Number of days per year that the line will run other product. |

|

0 |

|

0 |

|

|

|

Number of machines |

number |

|

Number of machines used for this process |

|

1 |

|

2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Working time |

working days / year |

|

Calculated automatically |

|

Husqvarna:

Can be more than 365 days per year if number of machines exceed 1

249 |

|

Husqvarna:

Can be more than 365 days per year if number of machines exceed 1

706 |

|

|

|

Working time |

minutes / year |

|

|

321210 |

|

917800 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Targets |

|

Capacity |

parts / year |

|

What is the target for annual capacity? |

|

500,000 |

|

1,200,000 |

|

|

|

Cycle time |

seconds / part |

|

What is the calculated cycle time for the equipment? If more than one cavity, then cycle time need to be divided by number of cavities. |

|

32 |

|

19 |

|

|

|

Right first time |

% |

|

What is the minimum for right first time product? ( no rejects, rework or scrap) |

|

97.0% |

|

97.0% |

|

|

|

Scrap parts |

% |

|

What is the maximum allowable scrap rate? (not reworkable) |

|

1.0% |

|

1.0% |

|

|

|

OEE, target |

% |

|

What is the minimum acceptable Overall Equipment Efficiency |

|

80.0% |

|

80.0% |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Theoretical Capacity |

parts / year |

|

Field calculated automatically. Purple is OK, Red is Not OK |

|

481,815 |

|

2,318,653 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Full run test results input |

|

Trial duration |

minutes |

|

The total duration of the trial from start to finish |

|

480 |

|

720 |

|

|

|

Parts made (total) |

parts |

|

Total number of parts made (including any rejects, rework and scrap) |

|

1023 |

|

1000 |

|

|

|

Rejects |

parts |

|

Total number of all rejects (including rework & scrap) |

|

21 |

|

88 |

|

|

|

Scrap parts |

parts |

|

Total number of scrap parts made (ie non-reworkable rejects) |

|

7 |

|

26 |

|

|

|

Downtime (incl breaks) |

minutes |

|

Total number of minutes when the process was not working |

|

34 |

|

56 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Full run test results |

|

Cycle time |

seconds / part |

|

These fields are calculated automatically

They will turn Purple if the result is acceptable compared to the target

They will turn Red if the result is unacceptable compared to target |

|

26.2 |

|

39.8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Right first time |

% |

|

|

97.9% |

|

91.2% |

|

|

|

|

|

|

|

|

|

|

|

|

|

Scrap |

% |

|

|

0.7% |

|

2.6% |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OEE |

% |

|

Field calculated automatically. Purple is OK, Red is Not OK |

|

111.3% |

|

40.1% |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Full run test capacity at targeted OEE |

parts / year |

|

Field calculated automatically. Purple is OK, Red is Not OK |

|

585,380 |

|

1,077,033 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CONCLUSION |

|

Field calculated automatically. Green is OK, Red is Not OK |

|

OK |

|

NOT OK |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

111.3% |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|