144x Filetype PDF File size 0.24 MB Source: www.forged-ironmongery.co.uk

What is Induction Heating?

Induction heating is a fast, accurate and contactless method of heating metals. It has many

applications but for blacksmiths, an induction heater avoids the time lost in lighting a forge and

bringing it up to temperature, this allows efficient forging of a single work piece. It offers a green

alternative to fossil fuels as there are no carbon emissions from the fuel.

Induction heating works by creating an electromagnetic field in a coil to transfer energy to the work

piece to be heated. When an electrical current transfers through the wire a magnetic field is created

around it. When that current changes it’s direction, the magnetic field created collapses, and is

produced in the opposite direction, as the current reverses direction. When a second wire is placed

in that alternating magnetic field an alternating current is generated in the second wire. The current

in the second wire is proportional to the current in the first wire and to the inverse of the square of

the distance between them. If we replace the wire in this scenario with a coil, the alternating current

on the coil creates an electromagnetic field. When you place a work piece such as steel to be heated

in the field, the work piece corresponds to the second wire and an alternating current is generated

in the work piece. The heat is generated in the work piece due to the I²R losses of the work piece’s

material resistivity. This is what is known as eddy current heating.

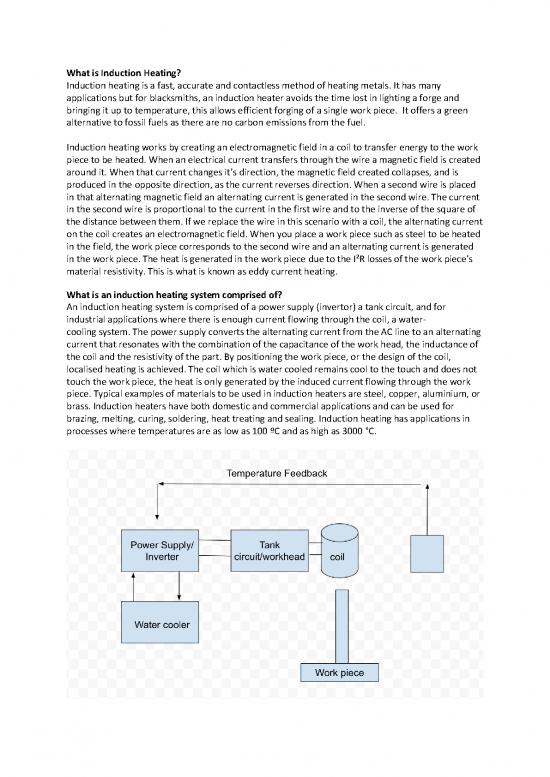

What is an induction heating system comprised of?

An induction heating system is comprised of a power supply (invertor) a tank circuit, and for

industrial applications where there is enough current flowing through the coil, a water-

cooling system. The power supply converts the alternating current from the AC line to an alternating

current that resonates with the combination of the capacitance of the work head, the inductance of

the coil and the resistivity of the part. By positioning the work piece, or the design of the coil,

localised heating is achieved. The coil which is water cooled remains cool to the touch and does not

touch the work piece, the heat is only generated by the induced current flowing through the work

piece. Typical examples of materials to be used in induction heaters are steel, copper, aluminium, or

brass. Induction heaters have both domestic and commercial applications and can be used for

brazing, melting, curing, soldering, heat treating and sealing. Induction heating has applications in

processes where temperatures are as low as 100 ºC and as high as 3000 °C.

How does an induction coil work?

The coil is used to transfer energy to the piece using an alternating electromagnetic field. The

alternating current flowing through the coil produces the electromagnetic field which then induces

the current flowing through the work piece to mirror image the current flowing through the coil. It is

the coil that regulates how effectively the piece is being heated and can vary in complexity but the

most commonly used is a multi-turn helical coil where the heating is determined by the number of

turns in the coil.

Things to consider

You will need to consider the material that you are using for the work piece. What you use will

determine the power required and the rate at which you will heat. For example, heating copper and

aluminium requires more power as it has low resistivity. Steel and iron heat easily as they have a

higher resistivity.

Another factor to consider is that some steels are magnetic and so both the steel resistivity and

hysteretic properties are used when heating with induction. Above the

Curie temperature (the temperature at which certain magnetic materials undergo a sharp change in

their magnetic properties – between 500-600 degrees Celsius), the steel loses its magnetic

properties but eddy current heating becomes the heating method for higher temperatures.

To determine the power, you need to consider the following factors. The size of the work piece, the

type of material you are using, the required temperature increases and the time

to reach temperature. Another factor is the operating frequency. Larger pieces will require a lower

frequency for efficient heating (>10khz) and more penetration from the generated heat whereas

small pieces benefit from a higher frequency of (>50 Kh z).

It may also be valuable to look at insulation techniques. As you work and the temperature of the

piece rises, so does the amount of heat you lose during use. Radiation and convection loss become a

progressively important factor with higher temperatures and insulation techniques can be used to

reduce the heat loss and minimize the power required from the system.

Operating Frequencies

The operating frequency for an induction heater is determined by the material to be heated. It is

essential to use the correct induction system that will deliver the correct power over the range of

frequencies, and which will be most appropriate for the work piece.

Generally, heating smaller parts requires a higher operating frequency whereas a larger workpiece

can be more efficiently heated with a lower operating frequency

To assist in understanding this we can look at the ‘skin effect’. In essence the skin effect is where

alternating current tends to avoid travel through the centre of a solid conductor, limiting itself to

conduction near the surface. This effectively limits the cross-sectional conductor area available to

carry alternating electron flow, increasing the resistance of that conductor above what it would

normally be for direct current. High frequency induction heating has a shallow skin effect which is

more efficient for smaller parts whereas with low frequency operating frequency the heat

penetrates deeper.

no reviews yet

Please Login to review.