248x Filetype PDF File size 2.31 MB Source: animation.rwth-aachen.de

Position-Based Rigid Body Dynamics

Crispin Deul, Patrick Charrier and Jan Bender

Graduate School of Excellence Computational Engineering

¨

Technische Universitat Darmstadt, Germany

{deul | charrier | bender}@gsc.tu-darmstadt.de

Abstract

Weproposeaposition-basedapproachforlarge-

scale simulations of rigid bodies at interactive

frame-rates. Our method solves positional con-

straints between rigid bodies and therefore inte-

grates nicely with other position-based methods.

Interaction of particles and rigid bodies through

common constraints enables two-way cou-

pling with deformables. The method exhibits

exceptional performance and stability while

being user-controllable and easy to implement.

Various results demonstrate the practicabil-

ity of our method for the resolution of colli-

sions, contacts, stacking and joint constraints.

Keywords: real-time, rigid body dynamics,

two-way coupling, position-based dynamics

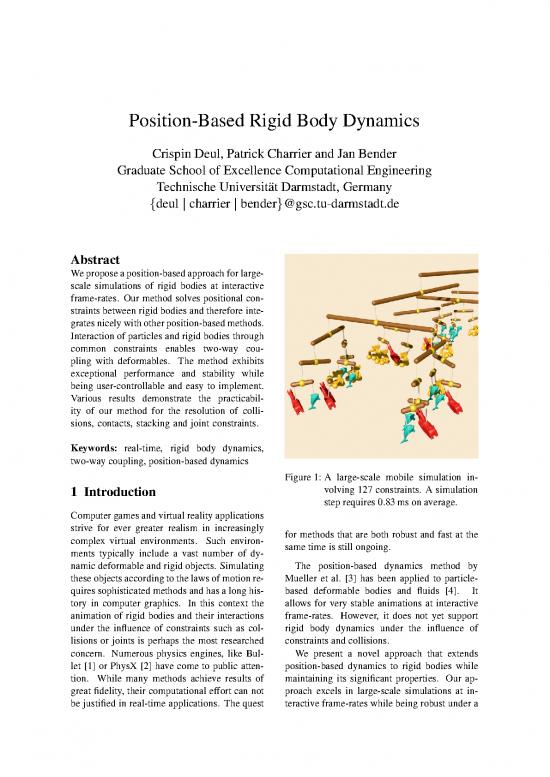

Figure 1: A large-scale mobile simulation in-

1 Introduction volving 127 constraints. A simulation

step requires 0.83ms on average.

Computergamesandvirtualreality applications

strive for ever greater realism in increasingly for methods that are both robust and fast at the

complex virtual environments. Such environ- sametimeis still ongoing.

ments typically include a vast number of dy-

namic deformable and rigid objects. Simulating The position-based dynamics method by

these objects according to the laws of motion re- Mueller et al. [3] has been applied to particle-

quires sophisticated methods and has a long his- based deformable bodies and fluids [4]. It

tory in computer graphics. In this context the allows for very stable animations at interactive

animation of rigid bodies and their interactions frame-rates. However, it does not yet support

under the influence of constraints such as col- rigid body dynamics under the influence of

lisions or joints is perhaps the most researched constraints and collisions.

concern. Numerous physics engines, like Bul- We present a novel approach that extends

let [1] or PhysX [2] have come to public atten- position-based dynamics to rigid bodies while

tion. While many methods achieve results of maintaining its significant properties. Our ap-

great fidelity, their computational effort can not proach excels in large-scale simulations at in-

be justified in real-time applications. The quest teractive frame-rates while being robust under a

vast number of constraints, as depicted in Fig- based on a prediction of the joint state [22], We-

ure1. Furthermore, the proposedmethodiseasy instein et al. [23] solved the nonlinear equation

to implement, controllable and supports two- by a Newton iteration method.

waycoupling of deformable and rigid bodies. Position-based methods became popular in

the last years since they are fast, robust and con-

2 Related Work trollable while no implicit time integration is re-

quired. A survey of position-based methods is

¨

presented by Bender et al. [24]. Muller et al. [3]

The field of rigid body dynamics has a long introduced position-based dynamics as a gener-

history in computer animation and may be de- alized framework capable of solving a large va-

composed into the four subfields integration riety of constraints. They demonstrated its ap-

schemes, collision detection, collision response plication on deformable solids [3, 25] and later

and constraint resolution. The survey of Bender also on fluids [4]. Diziol et al. [26] introduced

et al. [5] describes all subfields in more detail, a shape matching method with a volume conser-

but only the two latter ones are of primary inter- vation for deformable solids to achieve more re-

est in this paper. alistic results. In order to make shape matching

In previous work collision handling was per- ¨

more robust, Muller and Chentanez [25] added

formed by the application of forces [6], by solv- an orientation to the particles of their model.

inglinearcomplementaryproblems[7]orbyus- This allows them to simulate bodies with solid

¨

ing impulse-based methods [8, 9, 10]. Muller et components and basic joints. Although they

al. [3] even introduce a method that resolves col- treat each particle as a rigid body with posi-

lisions by directly modifying positions for the tion and orientation, they apply the standard

simplified case of individual particles. How- position-based constraints that depend solely on

ever, an extension to rigid bodies has not been particle positions. In constrast, our work incor-

shown yet. In contrast to that, Kaufman et porates position and orientation in the deriva-

al. [11] present a method which projects the ve- tion of constraint equations. This allows us

locities of the bodies in order to prevent pene- to form constraints between arbitrary points of

trations. Later, Kaufman et al. [12] introduced rigid bodies.

a staggering approach for frictional contacts.

Multi-impact problems were focused by Smith

et al. [13]. In order to increase the performance 3 Preliminaries

of large-scale simulations, shock propagation

methods were introduced [9, 14]. Furthermore, In this section we first start with a brief intro-

different GPU-based methods were presented to duction to the position-based dynamics frame-

simulate large systems in real-time [15, 16]. work (PBD). Then we continue with the basics

To simulate an articulated system with joints, of rigid body simulation.

equalityconstraintsaredefinedfortherigidbod- The original position-based dynamics ap-

ies. A classic approach to solve these constraints proach [3] is used to simulate a model defined

in real-time is to use reduced coordinate meth- byparticles and constraints between these parti-

ods. Featherstone demonstrated that a simula- cles. The constraints are solved at the position

tion with reduced coordinates can be performed level by applying correction displacements onto

in linear time for acyclic systems [17, 18]. Re- the particle positions. In order to measure the

don et al. [6] introduced an adaptive variant of constraint violation, preview positions of the

this approach which uses a reduced number of particles are computed in a first step by integrat-

degrees of freedom to improve the performance. ing the particle velocities under the influence

Baraff [19] introduced a Lagrange multiplier of external forces. Then the particle positions

method which also has a linear-time complex- are integrated with the new velocities yielding a

ity for acyclic models. Later, Bender [20, 21] symplectic Euler scheme. In the second step the

demonstrated that the idea of Baraff can also systemofconstraintsissolvedinaGauss-Seidel

be applied to impulse-based simulation. While typeiteration. The third step updates the particle

Bender proposed to solve a linearized equation velocities depending on the difference between

the particle positions at the start of the time step applying displacements to the according parti-

and the new particle positions multiplied by the cles. The displacements are computed by solv-

inverse time step size. In a final step the new ing constraints of the following form:

velocities are modified to handle friction and

damping. C(p+∆p)=0, (1)

As mentioned before, we want to solve con- where p = [p ,...,p ]T is the concatenated

straints on rigid bodies, which are defined by six 1 n

parameters. The translational motion parame- vector of particle preview positions and ∆p =

[∆p ,...,∆p ]T contains the corresponding

ters are the position x, the velocity v, and the 1 n

mass m, which rigid bodies have in common correction displacements.

with particles. In addition to that, the three ro- In order to solve a constraint function a first-

tational parameters are the orientation ϑ, the an- order Taylor approximation

gular velocity ω, and the inertia tensor I. C(p+∆p)≈C(p)+∇ C(p)·∆p=0, (2)

Theseparametersareemployedinasymplec- p

tic Euler scheme as follows. The equations for is used to linearize the constraint. However, this

velocity and position integration are defined by equation is underdetermined. By restricting the

F direction of the position correction to the gra-

v(t +h)=v(t )+ externalh dient direction this problem is solved [3]. The

0 0 m

final displacement vector is determined by

x(t +h)=x(t )+v(t +h)h

0 0 0

wC(p)

∆p =− i ∇ C(p), (3)

whiletheequationsfortherotationalparameters i

p

P

2 i

w ∇ C(p)

j j

p

are given by j

−1 where w is the inverse mass of particle p .

ω(t +h)=ω(t )+hI · i i

0 0 Asanextensiontotheparticleconstraint han-

(τexternal − (ω(t) × (I · ω(t)))) dling of PBD our approach handles constraints

q(t +h)=q(t )+ hω˜(t +h)·q(t ), between rigid bodies. In contrast to particles an

0 0 2 0 0

orientation is associated to rigid bodies. Points

p that are attached to a rigid body with index j

where ω˜ is the quaternion [0,ω ,ω ,ω ]. Af- i

x y z can be described by the following formula

ter the preview positions of the bodies are in-

tegrated with the equations above position con- p(x ,R(ϑ )) = x +R(ϑ )r , (4)

straints are solved in several iterations. How- i j j j j i

ever, in constrast to the original PBD approach, wherex isthecenterofmassandR(ϑ )thero-

that updates the velocities after the constraint j j

solver step, we update the velocities of con- tation matrix of the rigid body with index j. The

straints whenever a correction displacement is local position of the point i in the body frame

is encoded in r . Using the definition of body

applied to a rigid body. The required impulse to i

updatethevelocitiesiscomputedbemultiplying attached points (see Eq. 4) in the Taylor approx-

themassweighteddisplacementwiththeinverse imation of the constraint (see Eq. 2) yields:

time step size. By updating the velocities during C(p(x+∆x,R(ϑ+∆ϑ)))≈

the position iterations we can apply our friction C(p(x,R(ϑ)))+ (5)

resolution approach whose details are presented T T T T T

JC(x,ϑ)·[∆x ,∆ϑ ,...,∆x ,∆ϑ ] ,

in section 6. 1 1 n n

where x = [xT,··· .xT]T and ϑ =

1 n

T T T

4 Constrained Rigid Bodies [ϑ ,··· ,ϑ ] are the vectors containing all

1 n

positions and orientations of the n constrained

In this section we describe how to extend the bodies. Furthermore, the function p com-

PBD solver to solve constraints between rigid putes the concatenated vector of m positions

T T T

bodies. The standard solver works by itera- p = [p (x ,R(ϑ )) ,...,p (x ,R(ϑ )) ]

1 1 1 m n n

tively handling each constraint on its own by that are constrained by C(p). Due to the fact,

that the entries of p depend on a function (see 5 Joints

Eq. 4), the chain rule has to be applied to

the constraint function C(p) to compute its Defining translational joint constraints between

derivative. As a result, the gradient ∇ C(p) two rigid bodies is straight forward using the

p constraint definition of section 4. The transla-

in Eq. 2 is replaced by the k × 6n Jacobian

JC(x,ϑ) = �∂C ∂C of the constraint function tional constraints have in common that the dis-

∂x ∂ϑ tance of two joint points a and b, each attached

with respect to the rigid body positions and

orientations, where k is the dimension of the to one of the two bodies A and B, is constrained

codomain of C(p). to be zero. The only difference is the dimension

LetM bethe6×6massmatrixofrigidbody of the constraint space. A simple translational

j constraint is the ball joint

j with the mass on the first three entries of the

diagonal and the moment of inertia tensor Ij in C(a,b) = a−b=0

the lower right 3 × 3 submatrix. By rearrang- that removesalltranslationaldegreesoffreedom

ing Eq. 5 the same way that led from Eq. 2 to between the linked bodies. It follows that the

Eq. 3 and replacing the inverse particle mass wj joint points and with them the according bodies

with the inverse mass matrix M−1, the formula

j can not move away from each other. However,

to compute the vector of rigid body corrections the two bodies can freely rotate around the joint

for constraint C(p) is: position. In order to define a translational con-

straint that removes only two translational de-

[∆xT,∆ϑT,...,∆xT,∆ϑT]T = grees of freedom the constraint space has to be

i i n n (6)

−1 T −1 T−1 reduced to a plane. The plane is defined by the

−M JC JCM JC C(p), joint point of one of the two bodies and the plane

normal that is also attached to this body. It fol-

where the matrix M−1JT converts the mass lows that the joint points have to be projected

C

weighted displacement to a displacement in into the plane to measure the constraint viola-

−1 T−1

world space. The matrix JCM JC is the tion. Then, the correction is computed in the

mass matrix in constraint space. two-dimensionalconstraintspace. In a final step

The question now is how to parameterize the themassweightedcorrectiondisplacementmust

rotations of the rigid bodies to compute a Jaco- be projection back into the three-dimensional

bian JC that can be multiplied with the inverse space. Similarly, the constraint space of a joint

mass matrix M−1. Orientations can be param- constrainingonetranslationaldegreeoffreedom

j is defined by attaching a unit vector to one of the

eterized in different ways like Euler angles or

quaternions. Accordingly, all these parameteri- rigid bodies. Again, the constraint violation is

zations lead to a different Jacobian. Neverthe- measuredbyfirstprojectingthejointpointsonto

less, a solution can be found by starting at the the constraint space and then computing the dis-

velocity level. The relationship between angu- tance.

lar momentum and angular velocity is L = Iω. Constraints that remove only rotational de-

Taking the first order integration, with the as- grees of freedom can be defined analogously by

sumption that the axis of rotation stays constant constraining the orientation of the linked bodies.

during the time step, and rearranging the result

gives I−1Lh = ωh = ϑ, where h is the time 6 Collision Handling

step size. The vector ϑ represents a rotation of

|ϑ| about the axis ϑ/|ϑ| and is known as the ex- In this section we present our solution to handle

ponential map from R3 to S3 [27], where S3 is collisions, contact, and friction. In the follow-

the space of rotation quaternions . The paper of ing paragraphs we combine the terms collision

Grassia [27] also presents the derivation of the and contact under the term proximity and use

rotational part ∂R(ϑ)/∂ϑ of the Jacobian JC the special terms only where differences occur.

which is not repeated here.

Proximity Detection We perform only one

discrete proximity detection step to ensure a

no reviews yet

Please Login to review.