197x Filetype PDF File size 1.20 MB Source: www.mshs.com

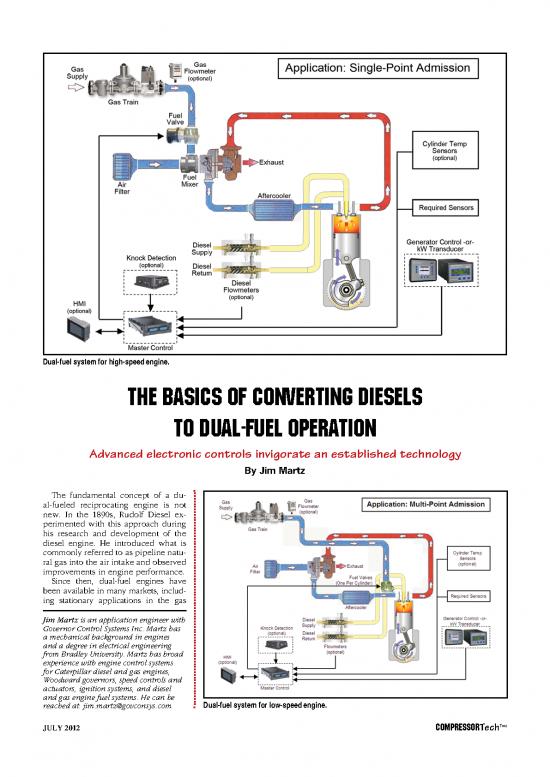

Dual-fuel system for high-speed engine.

The Basics of converTing Diesels

To Dual-fuel operaTion

Advanced electronic controls invigorate an established technology

By Jim Martz

The fundamental concept of a du-

al-fueled reciprocating engine is not

new. In the 1890s, Rudolf Diesel ex-

perimented with this approach during

his research and development of the

diesel engine. He introduced what is

commonly referred to as pipeline natu-

ral gas into the air intake and observed

improvements in engine performance.

Since then, dual-fuel engines have

been available in many markets, includ-

ing stationary applications in the gas

Jim Martz is an application engineer with

Governor Control Systems Inc. Martz has

a mechanical background in engines

and a degree in electrical engineering

from Bradley University. Martz has broad

experience with engine control systems

for Caterpillar diesel and gas engines,

Woodward governors, speed controls and

actuators, ignition systems, and diesel

and gas engine fuel systems. He can be

reached at: jim.martz@govconsys.com Dual-fuel system for low-speed engine.

July 2012 Compressor Two

Tech

opposed to using pre-turbocharger

fuel mixers.

The driving factor for the different

methodology is intake and exhaust

valve timing. There is a period of time

during the engine cycle when the in-

take and exhaust valves are open at

the same time. It is during this valve

overlap period that the cylinder is

flushed with clean, cool air, often

called “scavenging.”

In order for this operation to be

maintained in a dual-fuel engine, the

gas flow to the cylinder must be shut

off for a period of time to eliminate

the possibility of gas in the exhaust

manifold, which could be potentially

dangerous and explosive.

This interruption of the gas sup-

ply to the cylinder is accomplished

through the use of electrically oper-

ated solenoid valves. On a high-speed

engine, the overlap time of the valves

is much shorter than that of a low-

speed engine, so a continuous supply

of gaseous fuel flow is possible.

In low-speed applications, an elec-

tronic control drives the individual fuel

solenoid valves, regulating timing and

duration of fuel injection into the cylin-

der. This technique commonly allows

Multi-point fuel admission timing diagram.

compression industry. These types of Single-Point Fuel Admission

engines were used as early as the 1930s. Gaseous fuel admission in a high-

Today, the topic of decreasing de- speed industrial diesel engine is simi-

pendence on imported oil is a recur- lar to the methodology used on a tra-

ring issue. Emissions regulation and a ditional gas engine. The gaseous fuel

renewed push for clean technologies is admitted into the engine’s air intake

are at the forefront of many govern- through mixers installed upstream of

ment initiatives. the turbocharger(s) in a concept re-

With the prices of diesel fuel ris- ferred to as fumigation or single-point

ing and increasing regulation of admission. The incoming gas supply

emissions, machinery operators are is filtered prior to the pressure regula-

searching for alternatives to conven- tor and shutoff valves.

tional fuel. Modern dual-fuel systems The fuel flow is regulated through

incorporating electronic controls that the use of a butterfly-style throttle

enhance system performance repre- valve, which is governed by the main

sent a viable answer to the growing control system, before being admitted

concerns for the widespread installed through the mixer(s). The control sys-

base of diesel engines. tem uses a series of sensors and trans-

Since a diesel engine is a compres- ducers including fuel pressure, mani-

sion ignition engine and does not have fold air pressure, and temperature to

spark plugs or an ignition system, the calculate the optimum diesel-to-gas

primary diesel fuel is used as the ig- ratio and position the fuel valve(s)

nition source or pilot ignition for the to the optimum position to admit the

mixture in the combustion chamber. proper amount of gaseous fuel. This

Dual-fuel engines, therefore, retain technique commonly allows between

the fundamental principles of diesel 50 and 70% gas substitution rates and

engine operation and the efficiency higher in some applications.

of the diesel engine compression ratio

while enabling the engine to run on a Multi-Point Fuel Admission

cheaper, cleaner fuel. Gaseous fuel is not admitted into a

Industrial dual-fuel engine applica- low-speed engine in the same man-

tions are typically separated into two ner as in a high-speed engine. On

segments: low speed and high speed. low-speed engines, fuel is injected

Low speed is defined as 1000 rpm or through individual valves on each

lower. High-speed engines generally cylinder in a concept referred to as

run between 1200 and 1800 rpm. multi-point admission or injection as Comparison of fuels for dual-fuel diesels.

July 2012 Compressor Two

Tech

between 60 and 80% gas substitution

rates, and higher in some applications.

Benefits Of Dual-Fuel Operation

With the rising cost of diesel fuel,

and the fact that dual-fuel engines

considerably reduce diesel fuel us-

age, converting an engine to operate

primarily on a cheaper gaseous fuel is

economically attractive.

In addition, spark plugs and an ig-

nition system are not required. That

eliminates the costly spark plug main-

tenance associated with traditional nat-

ural gas engines and helps to further

reduce the overall cost of operation.

Depending on the expected number

of run-hours and the cost of diesel and

gaseous fuel, the up-front installation

cost of retrofitting an existing diesel

engine to dual-fuel operation can be

quickly recovered.

Gaseous fuels, and natural gas in

particular, are much cleaner burning

than diesel. Diesel engines that have Dual fuel overview on an HMI screen.

been converted to dual-fuel operation

have exhibited significant reductions

in NOx and CO2 over their original die-

sel operation. This is important in ar-

eas with increasingly tough emissions

regulations. In addition, on-site diesel

storage capacity can be reduced.

Retrofit systems can be installed in the

field in a short timeframe, minimizing

engine downtime. No modifications are

required to the core engine itself or to

the factory fuel management system.

With the engine’s main fuel becom-

ing gaseous fuel rather than diesel and

the electronic control system maximizing

fuel efficiency, installing an alternative

fuel system enables the on-site diesel

supply to last much longer, extending

engine uptime without compromising

performance.

Replacing diesel fuel with natural gas

typically extends engine maintenance

intervals and overall engine life. For

example, the life expectancy of cylin-

der head valve seats has been shown to

improve due to the cleaner combustion Dual fuel transferring on an HMI screen.

that gaseous fuel exhibits over diesel.

Benefits of the factory diesel engine, ignition temperature. The minimum directives such as ATEX in the European

including hardware ruggedness and op- temperature required for methane ig- Union or CSA in North America. These

erational efficiency, are maintained and nition without a spark or flame present directives are enforced wherever a po-

returning to operation on 100% diesel is about 1076°F (580°C). This is over tentially explosive environment is pres-

fuel is possible at any time. 500°F (260°C) higher than gasoline at ent and the main requirement is to pre-

Gasoline is a volatile fuel that is 536°F (280°C) and is therefore difficult vent the formation of this environment.

easily ignited. While diesel fuel is to auto-ignite. This is normally accomplished through

less volatile, it presents the same The narrow range of flammabil- the use of either double-walled gaseous

storage and handling problems. ity present with natural gas is also an fuel piping or single-walled piping in-

Comparatively, natural gas exhib- important aspect to safety. Natural gas stalled in a separate compartment. In

its many different characteristics. It only burns in concentrations between the case of double-walled piping, the

is buoyant at temperatures above 5% and 15%, making accidental igni- space between the walls can be con-

-160°F (-106°C), does not pool on the tion highly unlikely. Most importantly, tinuously ventilated.

ground, dissipates rapidly in the at- natural gas does not detonate in an In addition, gas detection sensors

mosphere, is non-toxic or corrosive, open environment. can be installed in the engine room to

and is environmentally safe. Some applications and installations of continuously monitor the environment

Natural gas also has a high auto- dual-fuel engines are subject to safety for the presence of gas. These sensors

July 2012 Compressor Two

Tech

are connected to an alarm system that factory dual-fuel engine. An engine de- Another example is a Human Ma-

can switch the gaseous fuel supply off signed specifically for dual-fuel opera- chine Interface (HMI). This enables

and either return the engine to op- tion can attain a higher diesel-to-gas all controls in a given system to have

eration on 100% diesel fuel or shut it ratio than a converted conventional their information displayed in one cen-

down completely. diesel. While manufacturers of these tral location for operator control and

engines claim operation on as little as system parameter monitoring. All basic

OEM Alternatives 1% diesel fuel, they may not be eco- engine parameters can be monitored

A number of OEMs produce conven- nomical for the general customer base along with diesel and gaseous fuel ra-

tional gas engines. Generally, spark- with installed diesel engines due to the tio, alarm status, real-time performance

ignited engines are designed by the high initial cost of investment. trending, and available remote access

OEM to operate on specific gaseous fu- Converting a conventional diesel via the Internet.

els, and therefore are optimized with a engine to an OEM factory style dual-

certain compression ratio, timing, and fuel system requires change of major Summary

air/fuel ratio to produce the highest effi- engine hardware such as pistons and Owners or operators of existing

ciency and power output with the low- heads, as opposed to a standard diesel diesel engines interested in cost sav-

est emissions possible. conversion that requires no change to ings should evaluate the benefits of a

However, there are a number of basic engine hardware. dual-fuel conversion.

disadvantages to them as well. First, While the concept of a dual-fuel

the power output of a spark-ignited Auxiliary Systems engine is not new, interest in this

gas engine is lower than that of a sim- In addition to the advantages of a technology is increasing due to rising

ilar sized diesel engine. This translates standard dual-fuel conversion, ad- costs of diesel fuel, more emphasis

to a higher capital investment during ditional features can be added to the on emission regulations, a desire to

initial installation. system for enhanced benefit. increase engine maintenance inter-

The spark ignition system itself has One such retrofit is a fuel flow me- vals, and a need to control overall

a high cost of maintenance as well. Al- tering system. When considering an cost of operation.

though many manufacturers continue alternative fuel system, it is neces- Offering ease of installation and

to invest in development of longer life sary to know how much diesel fuel is relative low cost of capital invest-

spark plugs, their operational life con- actually being saved and how much ment, dual-fuel conversions pro-

tinues to be a concern. Spark-ignited gaseous fuel is being used. A flow vide the ability to realize this cost

engines also run hotter than their die- metering system can be integrated to savings and adhere to regulations

sel counterparts, which significantly measure the supply of both fuels and through the use of gaseous fuel in

increases valve seat wear rates. the diesel return line to calculate fuel both low- and high-speed industrial

A small number of OEMs produce a usage and associated cost savings. engine applications.

A

Two

REPRINTED FROM JULY 2012 CompressorTech Copyright Diesel & Gas Turbine Publications

Printed in U.S.A.

no reviews yet

Please Login to review.