306x Filetype PDF File size 0.29 MB Source: injectionpumps.co.uk

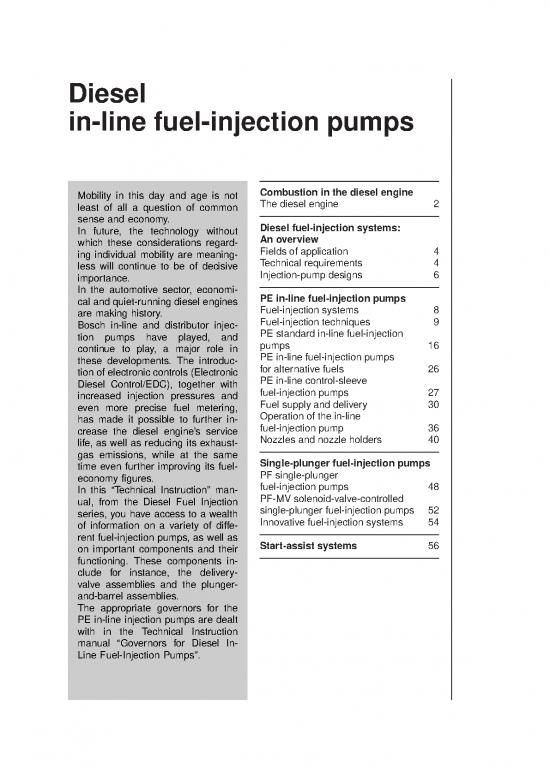

Diesel

in-line fuel-injection pumps

Mobility in this day and age is not Combustion in the diesel engine

least of all a question of common The diesel engine 2

sense and economy. Diesel fuel-injection systems:

In future, the technology without An overview

which these considerations regard- Fields of application 4

ing individual mobility are meaning- Technical requirements 4

less will continue to be of decisive Injection-pump designs 6

importance.

In the automotive sector, economi- PE in-line fuel-injection pumps

cal and quiet-running diesel engines Fuel-injection systems 8

are making history. Fuel-injection techniques 9

Bosch in-line and distributor injec- PE standard in-line fuel-injection

tion pumps have played, and pumps 16

continue to play, a major role in PE in-line fuel-injection pumps

these developments. The introduc- for alternative fuels 26

tion of electronic controls (Electronic PE in-line control-sleeve

Diesel Control/EDC), together with fuel-injection pumps 27

increased injection pressures and Fuel supply and delivery 30

even more precise fuel metering, Operation of the in-line

has made it possible to further in- fuel-injection pump 36

crease the diesel engine’s service Nozzles and nozzle holders 40

life, as well as reducing its exhaust-

gas emissions, while at the same Single-plunger fuel-injection pumps

time even further improving its fuel- PF single-plunger

economy figures. fuel-injection pumps 48

In this “Technical Instruction” man- PF-MV solenoid-valve-controlled

ual, from the Diesel Fuel Injection single-plunger fuel-injection pumps 52

series, you have access to a wealth Innovative fuel-injection systems 54

of information on a variety of diffe-

rent fuel-injection pumps, as well as Start-assist systems 56

on important components and their

functioning. These components in-

clude for instance, the delivery-

valve assemblies and the plunger-

and-barrel assemblies.

The appropriate governors for the

PE in-line injection pumps are dealt

with in the Technical Instruction

manual “Governors for Diesel In-

Line Fuel-Injection Pumps”.

In-line PE standard in-line – A number of high-pressure fuel-in-

fuel-injection jection lines, corresponding to the

pumps fuel-injection pumps number of engine cylinders, connec-

ting the injection pump and the injec-

tion nozzles,

Design and construction – The injection nozzles.

The standard PE in-line injection pumps The injection pump’s camshaft is driven

incorporate their own camshaft, and a by the diesel engine. Injection-pump

plunger-and-barrel assembly (pumping speed and crankshaft speed are identical

element) for each engine cylinder for 2-stroke engines. For 4-stroke engi-

(Fig. 1). nes, pump speed is the same as engine

camshaft speed, in other words half

The complete fuel-injection system is crankshaft speed.

comprised of: The drive between injection pump and

– A fuel-injection pump, engine must be as torsionally rigid as

– A mechanical (flyweight) or electronic possible if today’s high injection pres-

governor for control of engine-speed sures are to be generated.

and injected fuel quantity, There are a number of different sizes of

– A timing device (if required) for varying in-line injection pumps for the various en-

the start of delivery as a function of gine outputs.

engine speed, The injected fuel quantity depends upon

– A fuel-supply pump for delivering the the swept volume of the injection-pump

fuel from the fuel tank, through the fuel barrel, and maximum (pump-side) injec-

filter and the fuel line, to the injection tion pressures are between 400 and

pump, 1,150 bar.

Fig. 1

PES in-line fuel-injection pump

1 Delivery-valve holder, 2 Filler piece, 3 Delivery-valve spring, 4 Pump barrel, 5 Delivery valve, 6 Inlet

port and spill port, 7 Control helix, 8 Pump plunger, 9 Control sleeve, 10 Plunger control arm, 11 Plunger

return spring, 12 Spring seat, 13 Roller tappet, 14 Cam, 15 Control rack.

1

2

3

4

5

6

7

8 15

9

10

11

12

13

16 14 UMK0409Y

To lubricate the moving injection-pump A, M, MW, and P are manufactured in Standard

components (e.g. camshaft, roller tap- large batches (Fig. 2). in-line

pets etc.) there must be a certain amount The pump sizes ZW, P9, and P10 are fuel-

of oil in the injection pump. The injection available for even higher cylinder power injection

pump is connected to the diesel engine’s outputs. pumps

lube-oil circuit, and oil circulates through

the pump during operation. Method of operation

Each pump type is allocated to a given

type series, which in some cases overlap Interaction between the components

with respect to their power ranges. These The camshaft of the PE in-line injection

will be described in the following chap- pump is integrated in the aluminum pump

ters. housing. It is connected to the diesel en-

Two different construction principles are gine either through a timing device,

used for in-line injection pumps: The prin- through a coupling element, or directly. A

ciple for the M and A pumps, and that for roller tapper with spring seat is located

the MW and P pumps. above each camshaft cam. The spring

The power outputs of diesel engines seat provides a positive-drive connection

equipped with in-line injection pumps between pump plunger and roller tappet.

range from 10 to 70 kW per cylinder. This The pump plunger moves up and down in

broad power-output range is made possi- the pump barrel, and together these two

ble by the availability of a wide variety of components form the plunger-and-barrel

different pump versions. The pump sizes assembly (pumping assembly).

Tab. 1

Overview

Features PE in-line injection pumps

M A MW P1...3000 P7100...8000

Injection pressure 550 750 1100 950 1300

in bar (pump side)

Application Passenger Light to medium Heavy

cars commercial vehicles, commercial

and tractors, vehicles, indus-

vans industrial engines. trial engines.

Output per cylinder 20 27 36 60 160

in kW/cylinder

Fig. 2

In-line injection pumps. Size comparison (looking onto camshaft end)

M A MW P1…3000 P7100…8000

UMK0803Y17

no reviews yet

Please Login to review.